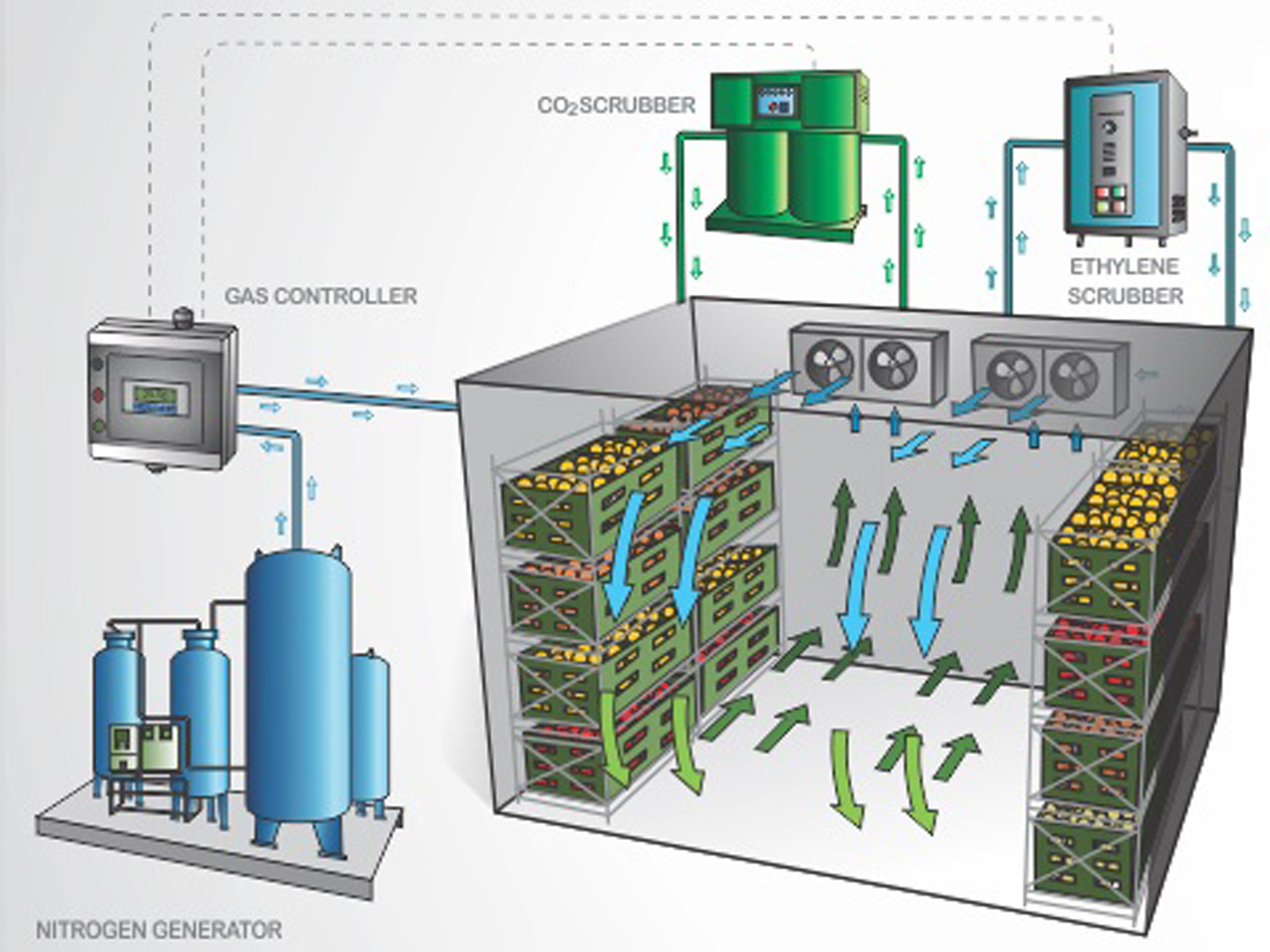

ULO (Ultra Low Oxygen) technology is one of top achievements in the long-term preservation of freshness and high quality fruit.

Ultra Low Oxygen technology represents the latest achievement in the long-term preservation of fruit. In order to preserve the high quality of the fruit from our orchards, we use low-oxygen air technology in specially enclosed chambers. The ULO regime in fruit chambers gives the opportunity to keep the whole yield of fruit kept and offered to the market all the time throught the whole year as if it were just picked. Thus, ULO technology allows apples to preserve unchanged properties for a long period of time without any chemical interventions, which significantly affects not only quality of the fruit. But also its nutritional properties (such as the content of the vitamin in fruit).

ULO

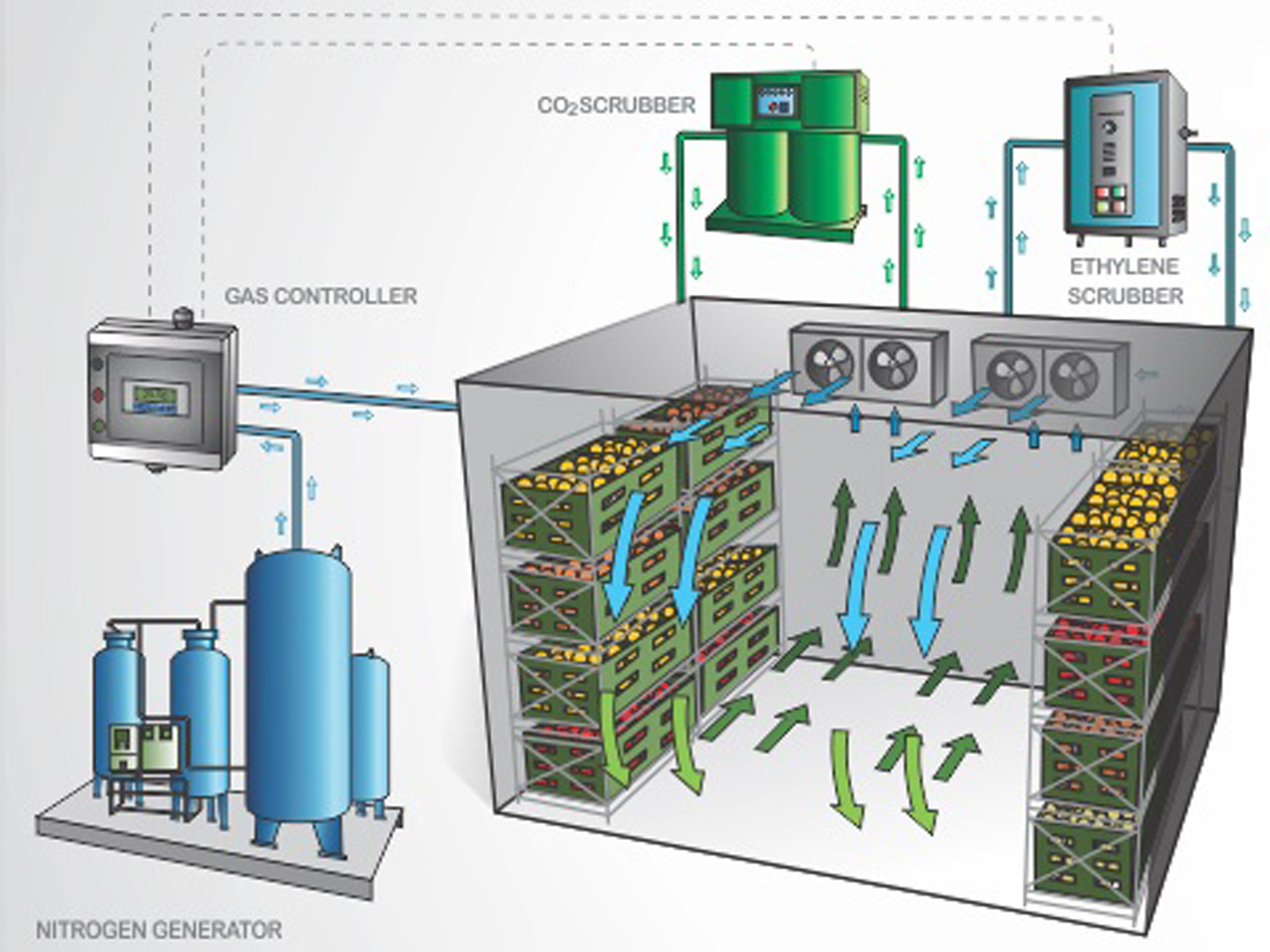

ULO (Ultra Low Oxygen) technology is one of top achievements in the long-term preservation of freshness and high quality fruit.

Ultra Low Oxygen technology represents the latest achievement in the long-term preservation of fruit. In order to preserve the high quality of the fruit from our orchards, we use low-oxygen air technology in specially enclosed chambers. The ULO regime in fruit chambers gives the opportunity to keep the whole yield of fruit kept and offered to the market all the time throught the whole year as if it were just picked. Thus, ULO technology allows apples to preserve unchanged properties for a long period of time without any chemical interventions, which significantly affects not only quality of the fruit. But also its nutritional properties (such as the content of the vitamin in fruit).

Capacity

Our ULO (Ultra Low Oxygen) cooling storage capacity is 10 000t.

We have a modern distribution centre for fresh fruit market. Within our hall we have a large, fully equipped manipulative space for sorting and packing fruit, including a ramp for easier loading packed goods.

Also, we have the possibility and ability to expand storage capacities, in line with the development of operations and expansion of the network of subcontractors.

Capacity

Our ULO (Ultra Low Oxygen) cooling storage capacity is 10 000t.

We have a modern distribution centre for fresh fruit market. Within our hall we have a large, fully equipped manipulative space for sorting and packing fruit, including a ramp for easier loading packed goods.

Also, we have the possibility and ability to expand storage capacities, in line with the development of operations and expansion of the network of subcontractors.

Sorting

Fruit sorting is done by the Aweta sorter.

By installing the latest optical sorting and calibration equipment, we have enabled controlled selection, washing and packing apples and after that, they are ready for delivery.

The Aweta sorter has a capacity of 3 to 7 tons of fruit per hour.

Each our apple after sorting and calibration retains the highest level of freshness and quality and, like that, it can be packaged in the packaging required by the costumers.

Sorting

Fruit sorting is done by the Aweta sorter.

By installing the latest optical sorting and calibration equipment, we have enabled controlled selection, washing and packing apples and after that, they are ready for delivery.

The Aweta sorter has a capacity of 3 to 7 tons of fruit per hour.

Each our apple after sorting and calibration retains the highest level of freshness and quality and, like that, it can be packaged in the packaging required by the costumers.

Packaging

Packaging is carried out in packaging at the customers request.

By using a several different types of packaging, we are able to respond to all requirements of our customers.

Aware the fact that quality and attractive packaging plays a major role in the sale, we paid special attention to the packaging process. Depending on the distance of the market, its characteristics and habits of consumers, we offer our customers the following packaging:

- box pallets,

- wooden crates (one row, two rows, three rows),

- plastic crates (one row, two rows, three rows),

- cardboard crates (one row, two rows, three rows),

- as well in plastic bags or baskets.

Packaging

Packaging is carried out in packaging at the customers request.

By using a several different types of packaging, we are able to respond to all requirements of our customers.

Aware the fact that quality and attractive packaging plays a major role in the sale, we paid special attention to the packaging process. Depending on the distance of the market, its characteristics and habits of consumers, we offer our customers the following packaging:

- box pallets,

- wooden crates (one row, two rows, three rows),

- plastic crates (one row, two rows, three rows),

- cardboard crates (one row, two rows, three rows),

- as well in plastic bags or baskets.

From production to You – How it’s made?

*This video was not made in our storage capacities, and it used only for displaying different production processes.